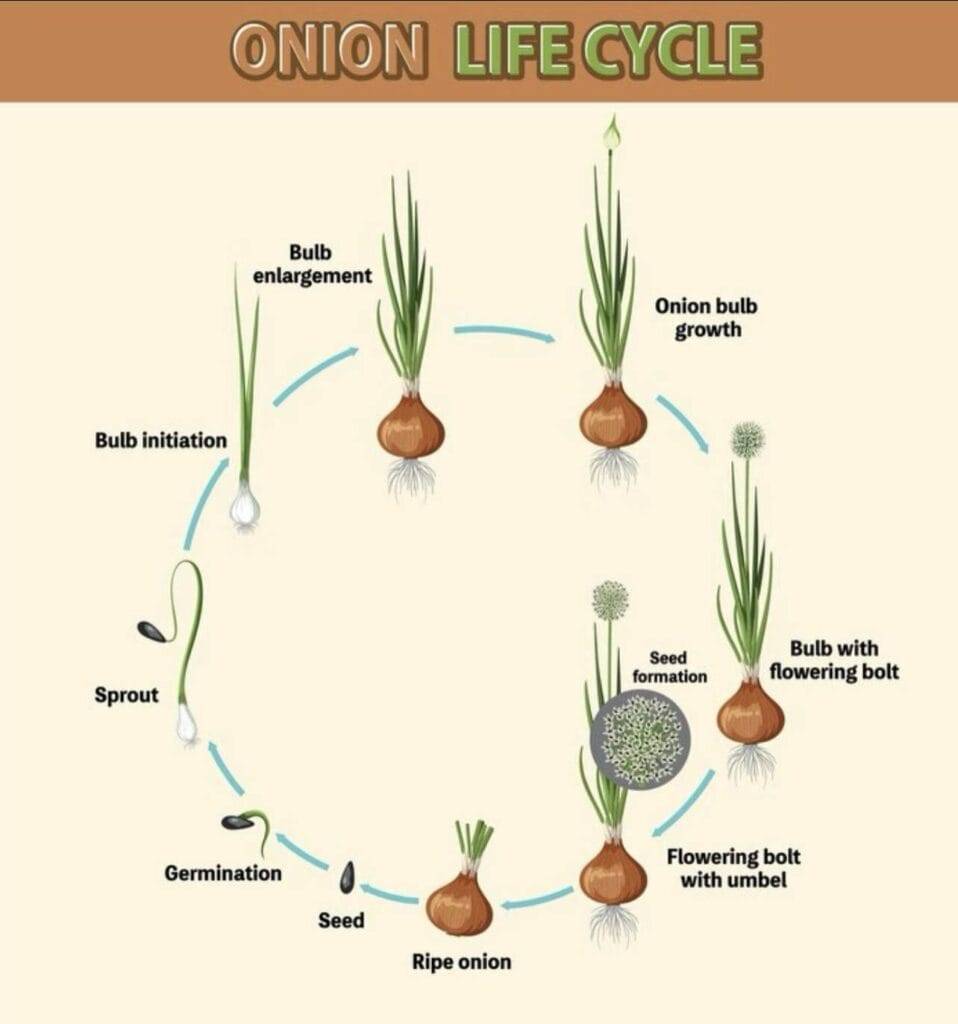

1.1 Basic principles of air suction seeding

Pneumatic Onion Seeder is a precision seeding device that uses air flow (negative or positive pressure) to extract, transport, and discharge seeds. The core principle is to generate adsorption force through aerodynamics, which adsorbs a single seed onto the hole of the sowing tray. When the seed rotates with the tray to the discharge port, the suction force disappears, and the seed falls evenly into the sowing ditch under the action of gravity and airflow.

This system consists of a vacuum pump, seed suction tray, suction pipe, seeder, trencher, soil covering device, and compaction wheel. Compared to traditional mechanical sowing, air suction technology achieves high-precision single seed sowing by adjusting vacuum pressure and aperture, especially suitable for small seed crops such as onions, carrots, celery, etc.

1.2 Application background of suction seeder in onion production

In foreign countries, especially in onion producing countries such as the United States, the Netherlands, and Australia, labor and seedling costs are relatively high. In order to reduce production costs and improve sowing efficiency, many growers are gradually shifting from “seedling transplanting” to “direct sowing”. The suction seeder played a key role in this transformation.

Its advantages are mainly reflected in:

Precise control of sowing rate can achieve 1-2 seeds per hole, saving seeds;

Reduce mechanical damage, seeds are transported under airflow without being subjected to mechanical compression;

Sowing evenly and with stable depth is conducive to neat emergence of seedlings;

High degree of automation, capable of supporting tractors to complete large-scale operations.

1.3 Structural characteristics of air suction seeder

The mainstream air suction onion seeders abroad usually include the following core modules:

1. Vacuum system: composed of a vacuum pump and an air tube, providing continuous suction.

2. Seed Plate: A disc with several micropores, slightly larger than the diameter of onion seeds.

3. Seed Hopper: a seed storage container with a measuring plate connected to the bottom for seed supply.

4. Sowing nozzle and conveying pipe: Direct the adsorbed seeds to the sowing ditch.

5. Trenching and soil covering device: Mechanical trenching, soil covering after planting, and compaction.

6. Row spacing adjustment and GPS control system (modern models): used for precise control of row spacing and sowing trajectory.

Different models can have single row, multi row, or combined structures. Modern equipment can also be equipped with electronic monitoring systems to detect seed leakage rates and air pressure fluctuations in real time, improving sowing accuracy.

2、 Preparation for planting onions with an air suction seeder

2.1 Seed Preparation and Adaptation

(1) Choose suitable varieties

It is advisable to choose varieties with high germination rate, strong embryonic roots, and low temperature tolerance for direct sowing.

(2) Seed grading and coating

Due to the extremely small suction aperture, onion seeds must have a uniform particle size. Screening, impurity removal, and coating treatment are commonly used abroad to make the seed surface smooth, round, and improve adsorption stability. Coated seeds can also reduce diseases and improve flowability.

(3) Seed drying and flowability testing

Before sowing, the moisture content of the seeds should be tested (generally controlled at 7-9%) to prevent clogging of the holes during seed suction. You can try suction on the seeder for a few minutes to observe whether there is excessive or insufficient suction, in order to adjust the vacuum pressure.

2.2 Soil and plot preparation

(1) Land preparation quality

Onion is a shallow rooted crop that needs to sprout in soft and delicate topsoil. Abroad, the three-step method of rotary tillage, leveling, and compaction is commonly used to ensure that the particle diameter of the surface soil does not exceed 1 cm. The surface should be flat and free of lumps, otherwise it will cause uneven sowing depth.

(2) Soil moisture and humidity

The soil should be at a humidity level where it can form clumps when held in hand and disperse upon landing. Excessive moisture can clog the trencher, while excessive dryness can cause the trench to collapse. When the air suction seeder operates in dry soil, it is also necessary to prevent the seeds from being blown out of the ditch by the airflow.

(3) Base fertilizer and pH management

Onion prefers slightly acidic to neutral soil (pH 6.0-6.8). Apply sufficient organic fertilizer or compound fertilizer (approximately N-P-K=10-10-10) before sowing, and thoroughly mix it into the plow layer. If the salt or nitrogen fertilizer is too high, the emergence of seedlings is easily inhibited.

2.3 Seeder Debugging and Parameter Setting

(1) Suction hole and vacuum pressure

The diameter of the suction hole is generally 1.0-1.2 mm, and the vacuum pressure is maintained at 3.5-4.5 kPa. If the suction force is too strong, it will cause double particles; If it is too weak, it will leak. Foreign manufacturers such as Stanhay and Monosem provide replaceable orifice plate kits for their models.

(2) Sowing depth and spacing

The suitable sowing depth for onions is 0.8-1.2 cm, with a row spacing of 25-30 cm and a plant spacing of 2-3 cm. The speed of the vacuum disk and the forward speed of the machinery need to be coordinated, generally controlled at 15-25 holes per minute for seeding.

(3) Sowing speed

Suggested homework speed is 3-5 km/h. Excessive speed can lead to an increase in leakage rate and uneven sowing depth; If it is too slow, it will affect efficiency and bed compaction.

(4) Covering soil and compaction

After broadcasting, the soil cover thickness is about 1 cm, and the roller pressure is controlled at 0.3-0.5 kg/cm ². The purpose of compaction is to bring the seeds into close contact with the soil, which is conducive to water absorption and germination.

3、 Operation process of air suction seeder

3.1 Pre sowing inspection and trial operation

Before formal sowing, the following checks need to be completed:

1. Whether the vacuum pump runs smoothly and there is no air leakage in the air pipe;

2. The suction hole is clean and free of residual dust;

3. The measuring disk rotates smoothly without eccentricity;

4. The seed delivery pipe is firmly connected to the trencher;

5. The pressure and angle of the soil covering device are appropriate.

Subsequently, an empty broadcasting experiment was conducted: the seed suction disk was started in a stationary state, and the adsorption and detachment conditions were observed. Then drive 5-10 meters on the plot for trial sowing, checking the spacing, sowing depth, and seed leakage rate. Adjust the vacuum degree or aperture as necessary.

3.2 Formal sowing operation steps

(1) Start up and ground entry

Lower the seeder to the operating depth;

• Activate the vacuum system and metering device;

Maintain a constant speed to prevent speed fluctuations.

(2) Seed suction and seeding process

When the vacuum suction cup rotates, the orifice attracts a single seed through suction. When turning to the sowing port, the suction disappears, and the airflow and gravity cause the seeds to fall into the sowing ditch. The distance between the seed drop port and the ground is about 5-8 cm to ensure the concentration of seed landing points.

(3) Covering soil and compaction

After sowing, immediately backfill with soil cover board, and then roll with a roller. Some models are equipped with a “secondary airflow” function, which releases a slight positive pressure at the moment of seed dropping to ensure that the seeds fall into the ditch bottom.

(4) Inspection and adjustment

Stop the machine for inspection after 100 meters of homework, dig trenches to check the sowing depth, seed spacing, and leakage rate. If the row spacing deviation exceeds ± 10%, the vacuum or velocity parameters need to be recalibrated.

3.3 Post broadcast management

(1) Water control during seedling emergence period

Keep the topsoil moist for 3-5 days after sowing, and use sprinkler irrigation if necessary. Avoid excessive flooding during the seedling emergence period, otherwise soil compaction may form.

(2) Monitoring of seedling emergence uniformity

Evaluate the seedling emergence rate approximately 10-14 days later. The ideal emergence rate should be above 85%. If the missed broadcast is wide, it can be manually supplemented or partially replayed.

(3) Weeds and pest control

Direct sowing of onion weeds is highly competitive, and in foreign countries, it is often combined with pre seedling herbicides (such as Pendimethalin) and shallow tillage for weed control. In terms of pests and diseases, pay attention to preventing and controlling downy mildew and onion thrips within 30 days after sowing.

4、 Technical points and fault prevention of air suction sowing onion

4.1 Key factors affecting seedling emergence

Explanation of Factors Affecting

Vacuum pressure directly affects the success rate of adsorption

The cleanliness of the suction hole and blockage of the hole can cause seed leakage

Uneven depth and consistency of sowing result in uneven emergence of seedlings

Soil moisture that is too dry or too wet is not conducive to germination

The uniformity of seeds affects the stability of single particle adsorption

In the standards of foreign seeder companies, the leakage rate should be less than 3%, the double seed rate should be less than 5%, and the sowing depth error should not exceed ± 3 mm.

4.2 Common faults and adjustment methods

1. Multiple omissions

→ Check if the pressure of the vacuum pump has decreased; The suction hole is blocked by dust; The surface of the seed is too wet.

2. Double particle adsorption

→ Reduce the vacuum pressure; Replace the small aperture suction cup; Add seed separation barriers.

3. Uneven broadcasting depth

Uneven ground surface or bouncing wheels; The land should be leveled or the angle of the roller should be adjusted.

4. Seeds fly out of the ditch

→ Strong airflow outlet; The air pressure at the seeding port should be lowered or the operating speed should be reduced.

5. Uneven emergence of seedlings

→ Large differences in soil moisture or uneven thickness of soil cover; Irrigation and soil covering systems need to be improved.

4.3 Safety and Maintenance Points

Clean the suction cup, trachea, and seeding nozzle after daily homework;

Regularly replace the vacuum pump filter element;

When parked for a long time, empty the remaining seeds to prevent mold growth;

• Keep the lubrication system normal to prevent gear jamming.

5、 Application Practice and Economic Benefit Analysis Abroad

5.1 Application in Typical Foreign Regions

In California, northern Netherlands, and Tasmania, Australia, air suction seeders have become one of the main equipment in onion broadcasting systems. It is equipped with a GPS guidance system, which can achieve 8-12 rows of synchronous sowing, with a working width of up to 3-4 meters.

The experimental data shows that:

Increase sowing efficiency by 60-80%;

• Improve seedling uniformity by 15-20%;

Reduce seed usage by 25-35%;

Reduce labor by more than 50% per unit area.

5.2 Economic and Management Benefits

The initial investment for air suction seeders is relatively high (about 10000-20000 US dollars per unit), but by saving labor and seeds, the cost can be recovered within 2-3 years.

Taking a 100 hectare onion field as an example:

The traditional manual transplanting mode has a labor cost of about 400 US dollars per hectare;

After adopting an air suction seeder, the price was reduced to $120 per hectare;

The overall cost has been reduced by about 35%.

Meanwhile, due to the neat spacing of mechanical sowing plants and improved lighting and ventilation, the yield can be increased by 10-15%.

5.3 Technology Promotion and Localization Challenges

In the promotion process, the main challenges include:

Lack of understanding of equipment maintenance and vacuum systems;

Local soil has high viscosity and is prone to clogging pores;

Small farmers have a low degree of mechanization.

Therefore, foreign experience suggests conducting demonstration field trials before promotion and establishing a shared agricultural machinery service model, so that small-scale farmers can also benefit.

6、 Conclusion and Future Prospects

The application of suction onion seeders has shifted direct onion sowing from “extensive operation” to “precision mechanization”. Its precise measurement, uniform sowing depth, and high efficiency characteristics have significantly improved the quality of sowing and economic benefits.

The future development directions include:

1. Intelligent regulation: Automatically detect vacuum pressure, seeding depth, seeding volume and adjust them in real time;

2. Data management: Combining IoT monitoring of seeding density and plot parameters;

3. Lightweight and multifunctional integration: synchronized operation with film covering, fertilization, and drip irrigation;

4. Localized adaptive design: Optimize the suction structure and power system for different soil structures and climatic conditions.

In summary, the suction onion seeder is not only the core equipment for mechanized sowing, but also an important technical support for promoting the development of modern onion industry towards high efficiency, precision, and sustainability!