In modern agriculture, our air-suction seeder stands out as a core equipment for farmers looking to increase planting efficiency and cut production costs, thanks to its perfect combination of technological innovation and practical adaptability. Taking air-suction precision seeding technology as its core, the seeder is equipped with an enlarged, thickened, and detachable soil collecting plate, as well as an integrated rotary tillage and ridging system. It has made significant breakthroughs in seed and labor saving, ridging quality, and machine flexibility, perfectly meeting the operational requirements of both large-scale planting and scattered plot farming.

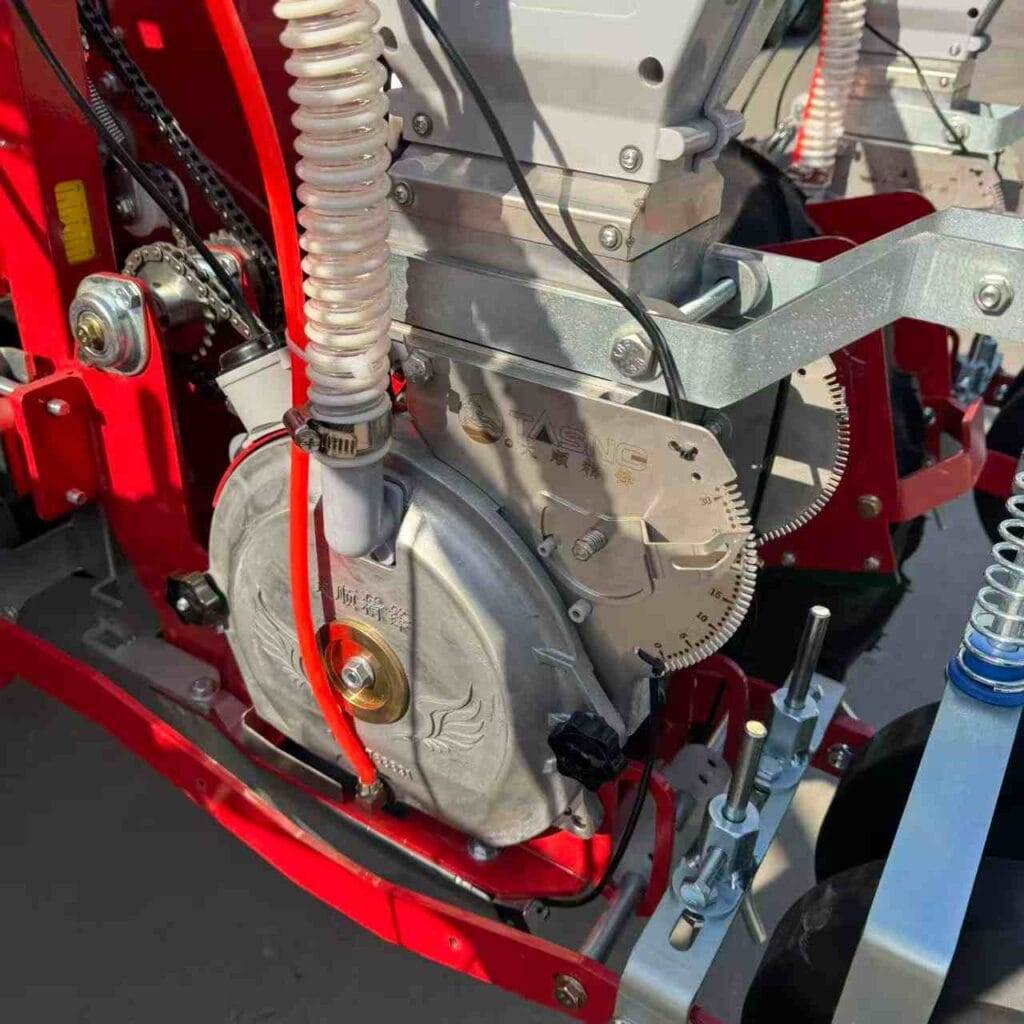

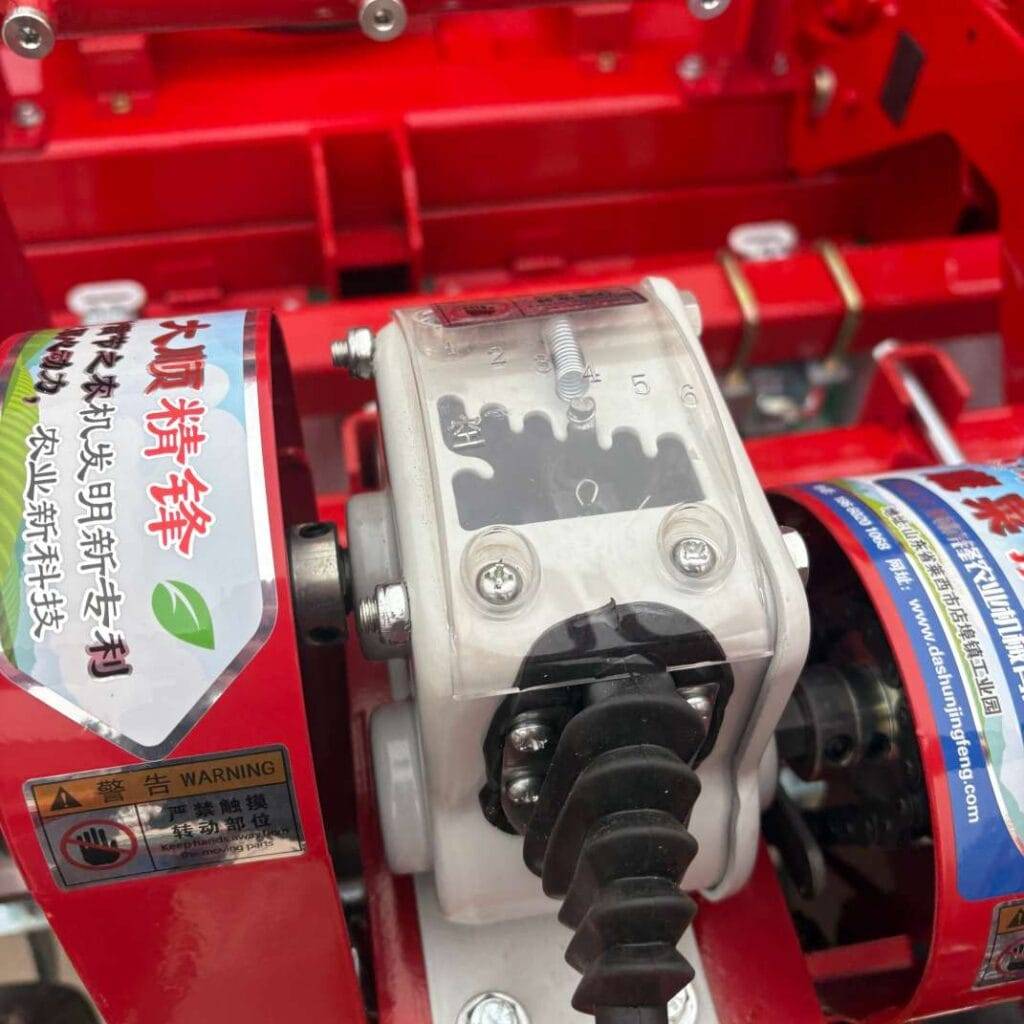

Air-suction seeding technology has essentially solved the long-standing issues of resource waste and inefficiency in traditional seeding. Based on the principle of vacuum negative pressure adsorption, the seeding unit of our seeder is equipped with a seed metering device, realizing the precision seeding pattern of “one seed per hole” and effectively avoiding missed seeding and reseeding. Compared with traditional broadcasting methods, the seed utilization rate is increased by more than 70%, which substantially reduces the cost of planting high-quality crop seeds. Moreover, the machine is equipped with a plant spacing adjustment box that can accurately regulate plant spacing. The uniform plant spacing ensures that each vegetable has adequate growth space and nutrients, reducing the need for manual thinning in the later stage. The seeder is simple to operate; one person can easily finish multiple processes such as rotary tillage, ridging, fertilization, and air-suction seeding, reducing labor costs by over 60% and markedly improving field operation efficiency.

The enlarged, thickened, and detachable soil collecting plate is designed to further enhance the quality of ridging operations. With a robust and durable structure, this soil collecting plate can efficiently collect loose and broken soil at the bottom of furrows after rotary tillage, which is then used for ridging and shaping. The ridges formed are full, regular, and of uniform density, not only providing a favorable soil environment for seed germination but also making it easier to lay drip irrigation pipes and cover films in subsequent operations. In addition, the detachable feature of the soil collecting plate allows for convenient removal during transportation to save space and prevent damage, and it can be quickly installed when it is time to work in the fields.

The integrated design of the rotary tillage and ridging mechanism plays a key role in improving the equipment’s mobility. This design cleverly incorporates the ridging device into the main body of the rotary tiller, greatly shortening the machine’s length and making its layout more compact. Compared with traditional split-type agricultural machinery, it has a smaller turning radius, allowing for flexible turning and precise positioning in narrow plots, irregular fields, and around ridge edges. This effectively minimizes operational dead angles and improves land utilization. The compact body design also reduces the difficulty of operating the machine, enabling stable operation even in complex terrains and adapting to the operational needs of different planting scales. By integrating technological innovation with practical design, this air-suction seeder offers farmers an efficient, hassle-free, and low-cost planting solution, becoming a practical tool for promoting the refined and efficient development of modern agriculture.