High-Accuracy Onion Planting Solution for Modern Agriculture

- Introduction: The Challenge of Onion Planting

Onion cultivation is one of the most demanding segments in vegetable production. Unlike large-seed crops such as corn or beans, onion seeds are extremely small, lightweight, and irregular in shape. This makes uniform planting, accurate spacing, and stable emergence difficult to achieve using traditional mechanical seeders or manual sowing methods.

In many regions around the world, onion growers still face common problems such as:

• Uneven seed distribution

• High seed wastage

• Inconsistent plant spacing

• Poor germination uniformity

• Excessive labor costs

To address these challenges, vacuum precision onion seeders, also known as air suction onion seeders, have become an essential solution for modern, large-scale, and precision-oriented agriculture.

Our Vacuum Precision Onion Seeder is designed and manufactured specifically for high-efficiency onion planting, combining advanced air suction technology, durable mechanical structure, and flexible configuration options to meet the needs of growers worldwide.

⸻

- What Is a Vacuum Precision Onion Seeder?

A vacuum precision onion seeder is an agricultural planting machine that uses negative air pressure (vacuum suction) to pick up, transport, and release individual onion seeds at precisely controlled intervals.

Unlike conventional seeders that rely on gravity or mechanical agitation, a vacuum seeder ensures:

• One seed per hole

• Consistent spacing

• Uniform planting depth

• High planting accuracy

This technology is particularly suitable for:

• Onion seeds

• Leek seeds

• Chive seeds

• Small vegetable seeds

⸻

- Working Principle of the Vacuum Onion Seeder

The working principle of the vacuum precision onion seeder can be summarized in five key steps:

3.1 Vacuum Generation

A high-performance fan or turbine creates negative pressure inside the seeding system. This vacuum is distributed evenly to each seeding unit.

3.2 Seed Pickup

As the seed plate rotates, vacuum holes on the plate pick up onion seeds from the seed hopper. The vacuum force ensures that only one seed adheres to each hole.

3.3 Excess Seed Removal

If more than one seed attaches to a hole, an adjustable seed scraper or air release mechanism removes the excess seeds, guaranteeing single-seed precision.

3.4 Seed Release

When the seed plate rotates to the release point, the vacuum is cut off, allowing the seed to fall freely into the seed tube.

3.5 Precise Placement

The seed is guided into the furrow at a consistent depth and spacing, followed by soil covering and compaction to ensure optimal seed-to-soil contact.

⸻

- Key Features of Our Vacuum Precision Onion Seeder

4.1 High Precision Seeding Accuracy

• Single-seed placement rate up to 98–99%

• Minimal missing or double seeds

• Ideal for hybrid and high-value onion seeds

4.2 Adjustable Row Spacing and Seed Spacing

• Row spacing customizable according to agronomic requirements

• Seed spacing adjustable to suit different onion varieties and planting densities

4.3 Compatible with Multiple Seed Sizes

• Interchangeable seed plates

• Suitable for pelleted and non-pelleted onion seeds

• Easy plate replacement without special tools

4.4 Stable Vacuum System

• Optimized air channel design

• Uniform suction pressure across all rows

• Reliable performance even at higher operating speeds

4.5 Durable and Heavy-Duty Construction

• High-strength steel frame

• Corrosion-resistant components

• Designed for long service life in various soil conditions

⸻

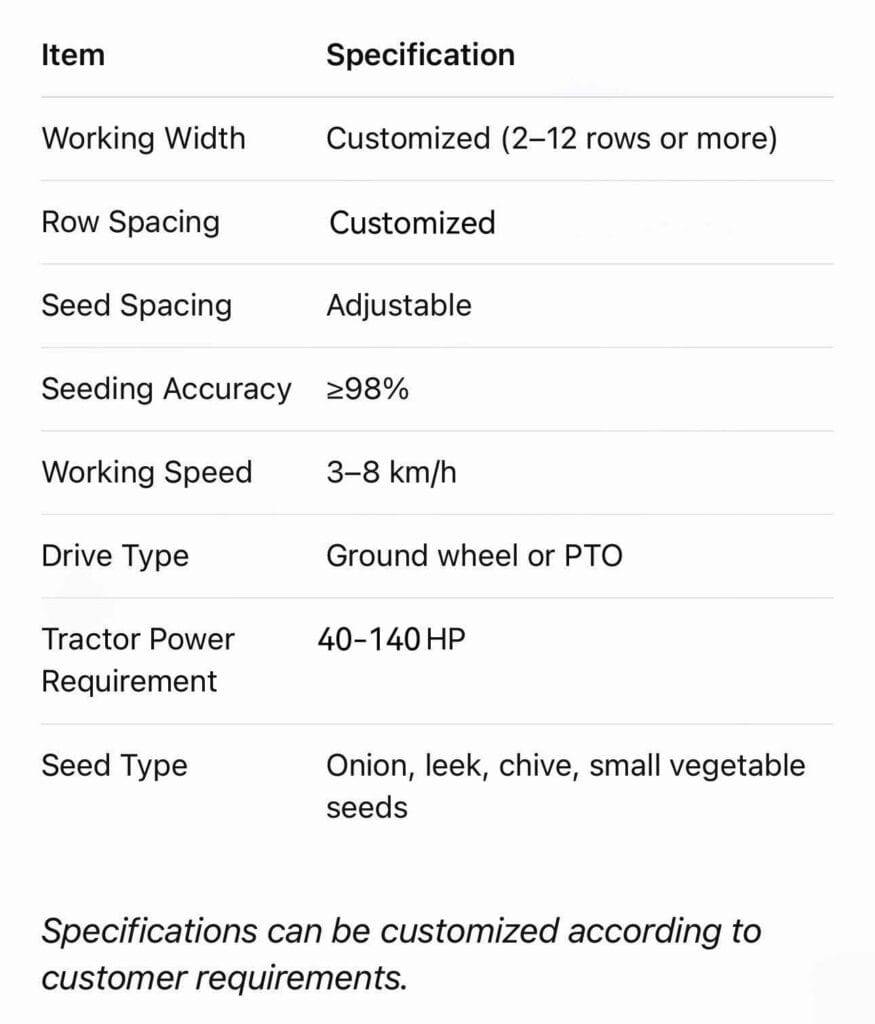

- Technical Specifications (Customizable)

- Advantages Compared with Traditional Onion Seeding Methods

6.1 Reduced Seed Cost

Precision placement drastically reduces seed wastage, especially important for expensive hybrid onion seeds.

6.2 Higher Yield Potential

Uniform plant spacing leads to:

• Better nutrient utilization

• Balanced plant growth

• Higher marketable yield

6.3 Labor Saving

One machine can replace multiple manual workers, significantly lowering labor dependency.

6.4 Improved Field Uniformity

Even emergence and consistent plant size improve harvesting efficiency and crop quality.

⸻

- Applications and Suitable Farming Scenarios

Our vacuum precision onion seeder is suitable for:

• Open-field onion cultivation

• Raised bed planting

• Commercial vegetable farms

• Contract farming operations

• Export-oriented onion production

It performs excellently in:

• Sandy soil

• Loamy soil

• Well-prepared clay soil

⸻

- Designed for Global Markets

Our machines are widely exported and adapted to different regions, including:

• North America

• Europe

• South America

• Middle East

• Africa

• Southeast Asia

We provide:

• Multi-language manuals

• International standard components

• Voltage and tractor compatibility options

⸻

- Manufacturing Strength and Quality Control

As a professional agricultural machinery manufacturer, we control the entire production process:

9.1 In-House Manufacturing

• Frame welding

• CNC machining

• Surface treatment

• Final assembly

9.2 Strict Quality Inspection

• Vacuum pressure testing

• Seeding accuracy testing

• Field simulation testing

9.3 International Standards

• ISO quality management system

• CE-compliant design available

⸻

- Customization and OEM / ODM Services

We offer flexible customization options, including:

• Row number customization

• Color and branding

• Logo and nameplate

• Packaging solutions

• OEM / ODM cooperation

Whether you are a distributor, importer, or brand owner, we can provide a complete solution.

⸻

- Easy Operation and Maintenance

11.1 User-Friendly Design

• Simple adjustment mechanisms

• Clear scale markings

• Quick seed plate replacement

11.2 Low Maintenance Cost

• Few wearing parts

• Easy cleaning after use

• Long service intervals

⸻

- After-Sales Support and Service

We provide comprehensive after-sales support:

• Online technical guidance

• Installation and operation videos

• Spare parts supply

• Long-term technical consultation

Our goal is to ensure stable operation throughout the planting season.

⸻

- Why Choose Our Vacuum Precision Onion Seeder?

• Professional manufacturer with years of experience

• Proven performance in global markets

• Competitive factory-direct pricing

• Reliable quality and service

We focus not only on selling machines, but on helping growers improve productivity and profitability.

⸻

- Future-Oriented Precision Agriculture

With the rapid development of precision agriculture, vacuum seeding technology will play an increasingly important role in vegetable production. Our onion seeders are designed with future upgrades in mind, allowing integration with:

• Precision farming systems

• Smart farm management

• Data-driven planting strategies

⸻

- Conclusión

The Vacuum Precision Onion Seeder is an ideal solution for growers seeking higher efficiency, better accuracy, and lower production costs. By adopting advanced air suction technology and robust mechanical design, this machine ensures uniform onion planting and stable crop establishment.

Whether you are a large-scale commercial farm, an agricultural service provider, or a machinery distributor, our vacuum precision onion seeder offers a reliable and profitable investment for modern onion cultivation.