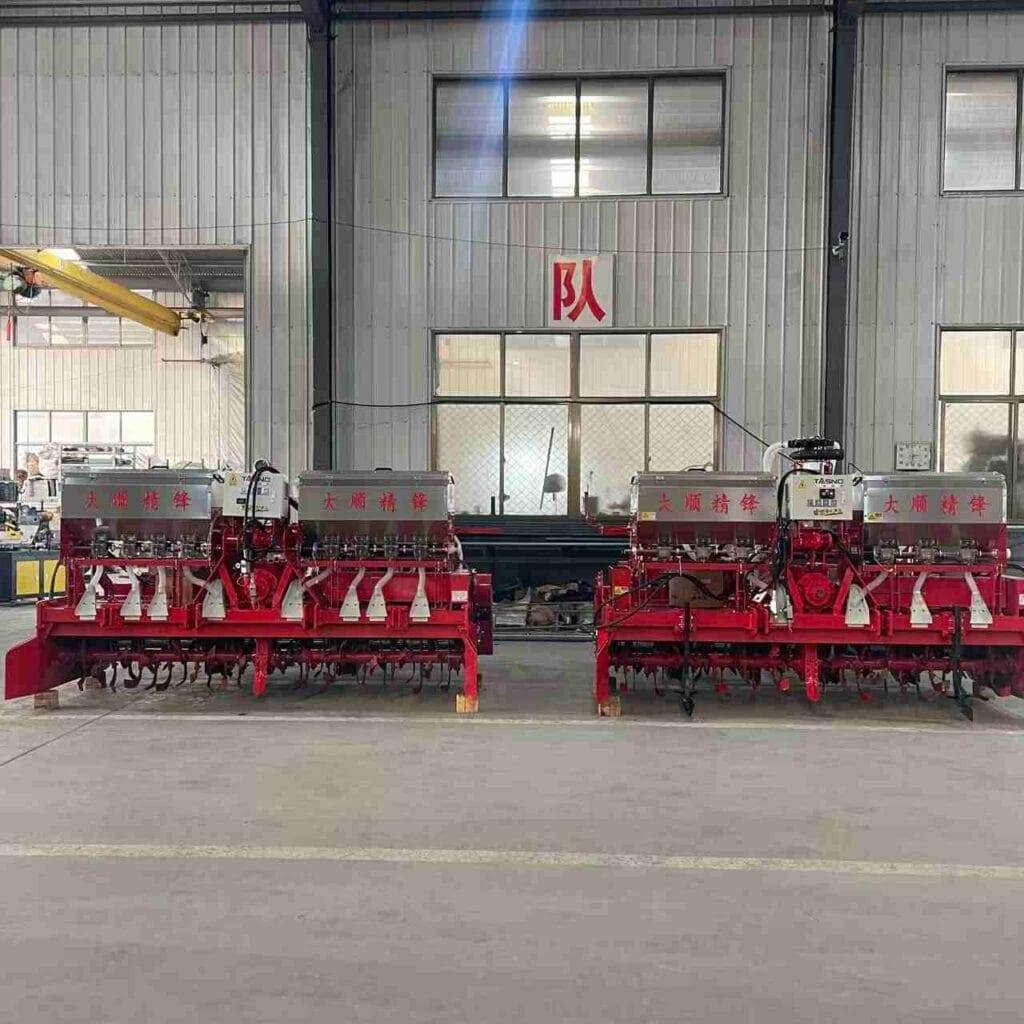

Modern agriculture thrives on efficiency and sustainability, and nothing embodies this better than the pneumatic precision seeder crafted by a source factory with a decade of specialized experience in agricultural machinery manufacturing. For more than ten years, this enterprise has been deeply engaged in the R&D and production of pneumatic seeders, taking farmers’ pain point of seed waste as its core research direction and integrating technological innovation into every link of product development— ultimately creating a seeding solution that redefines seed conservation in modern farming.

What sets this source factory apart is its ten years of unbroken focus and on-the-ground production experience. From the early days of learning and exploring core technologies to now leading independent innovation in the pneumatic seeder industry, the factory has always stood side by side with farmers, witnessing the transformation of agricultural equipment from mere functionality to high efficiency and precision. Equipped with a full set of advanced production lines, the factory controls every production process with rigorous standards: core parts are processed with high precision, assembly is finished by skilled workers, and all finished products undergo strict quality testing. This mature production system ensures the reliability and stability of each pneumatic seeder, while its customized product designs for different crops have formed a diverse product range, meeting the planting needs of vegetables, medicinal herbs and various cash crops.

The key to the pneumatic seeder’s extraordinary seed-saving performance is its cutting-edge vacuum negative pressure seed suction technology, which has been refined over a decade of continuous improvement. The factory’s R&D team has optimized every detail of the technology, achieving precise millimeter-level control over seed sowing. When the machine operates, the vacuum pump generates a steady negative pressure that securely holds seeds on the micron-scale holes of the seed metering disc. With the precise mechanical operation, seeds are released exactly at the preset positions, achieving one seed per hole with zero deviation. Unlike traditional seeding methods that waste a large number of seeds due to uneven sowing, this precision seeding technology maximizes seed utilization, increasing it by more than 60% and fundamentally solving the problem of seed waste in farming.

For farmers, this technological innovation brings direct and substantial benefits. Seed costs are significantly reduced, especially for high-value crops where seed expenses account for a large part of production costs. Moreover, the uniform plant spacing achieved by precision seeding ensures that each seedling has sufficient growth space and nutrients, avoiding overcrowding and nutrient competition. This leads to healthy and consistent seedling growth, eliminates the need for manual thinning, and greatly improves the quality and yield of harvested crops. It is not just a seeding machine, but a powerful tool that helps farmers cut costs, save labor and boost profits.

A decade of time has forged unparalleled technological strength, and persistent craftsmanship has built an excellent brand reputation. This source factory has turned its ten years of experience into tangible value for farmers through unremitting innovation and strict quality control. Its pneumatic seeder is more than just an agricultural machine; it is a testament to the factory’s commitment to agricultural modernization. As the agricultural industry continues to develop, the factory will keep innovating and optimizing its products, bringing the revolutionary seed-saving technology to more farmers, and contributing its professional strength to the development of efficient and sustainable modern agriculture with its unwavering craftsmanship and sense of responsibility.